-

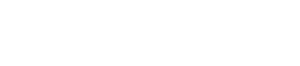

LOWCELL polypropylene(PP) foam board medicine, food, cosmetics transfer box 3 times

Lowcell is a supercritical non-crosslinked continuously extruded foamed polypropylene board with a closed-cell independent cell structure. The foaming ratio is 3 times, the density is 0.4-0.45g/cm3, and the thickness specifications are available in different thicknesses of 3-5mm. Compared with traditional solid polyethylene materials, it has many obvious advantages. First of all, the cost of the board is close to that of traditional polyethylene solid boards, and there will be no pressure to increase costs. Secondly, the high-temperature resistance of the raw material polypropylene itself can ensure that it is not easily deformed in high-temperature environments; good low-temperature resistance can also improve its strength and prevent it from becoming brittle in low-temperature environments.

We launch this transfer box made of high-quality 3 times PP foam board. It is a multi-functional transfer product suitable for pharmaceutical, food and cosmetics industries. It has excellent thermal insulation properties and compressive strength to protect products from damage during transit. Primarily designed to meet the needs of the pharmaceutical, food and cosmetics industries, it ensures the safe transit and storage of products. It has a lightweight design that is easy to carry and stack, which can save transportation and storage space. Moreover, the box adopts a drawer-type design for easy access and storage of products. This design not only reduces friction during storage of products, but also provides convenience of use.

-

LOWCELL H protective polypropylene(PP)foam board 3.0mm

Lowcell H is a carbon dioxide non-crosslinked extruded foamed polypropylene or polyethylene board with closed cell bubble structure.1.3 times of foaming ratio, density 0.6-0.67g/cm3, thickness 2-3mm. It is made by coextrusion in the cavity of the machine die head and has a three-layer structure. The upper and lower surface layers are blue or green solid polypropylene(PP) or Polyethylene(PE), and the surface is pressed with leather lines, which has the effect of anti-skid.. The middle layer is black low expanded foam, It not only has good cushioning and protection during impact, but also has high hardness and compressive performance.

-

LOWCELL H protective polypropylene(PP)foam back board

Lowcell H is a supercritical non crosslinked extruded foamed polypropylene(PP) board with closed cell and independent bubble structure. 1.3 times of foaming ratio, density 0.6-0.67g/cm3, thickness 1.0-1.2mm. It has a special three-layer structure made by coextrusion in die head cavity.The upper and lower surface layers are solid polypropylene(PP), and the surface is pressed with frosted lines, which is not easy to be scratched. The middle layer is black and low foaming, which not only takes into account the lightness, but also has high hardness and cushioning.

-

LOWCELL polypropylene(PP) foam board Tool Box 10.0mm

Lowcell is a supercritical non-cross-linked extruded foamed polypropylene board with a closed-cell independent bubble structure. With a foaming ratio of 2-3 times, a density of 0.4-0.45g/cm3 and a thickness of 10mm, it is an extremely high-performance super-thick polypropylene foam board with good impact resistance and corrosion resistance, and has better rigidity and compression resistance. In modern life, tool boxes are not only essential tools for craftsmen and DIY enthusiasts, but also indispensable items in homes and workplaces. Our new 10mm high-strength PP foam board tool box is designed to meet a variety of needs. This tool box is both lightweight and durable, and can effectively protect your tools from the outside environment. Whether in a humid workshop or outdoors in direct sunlight, this tool box can maintain its excellent performance, ensuring that your tools are always in the best condition, making it your ideal DIY tool box.

-

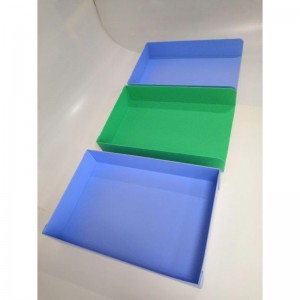

LOWCELL polypropylene(PP) foam sheet partition materials

LOWCELL polypropylene(PP) foam sheet is Carbon dioxide(CO2) SCF non-crosslinked with closed cell foam extrusion.This is better multi-purpose materials. The foam sheet is lighter, higher strength, fully recyclable,smooth surface and low VOC. Mostly use polypropylene(PP)foam sheet(expanded 3 times) as packaging inner material.The product lineup offers greater benefits by using the general-, antistatic- and conductive-grade products according to the usage environment.According to your needs, we can customize any shape of partition materials.Colors can also be customized.

-

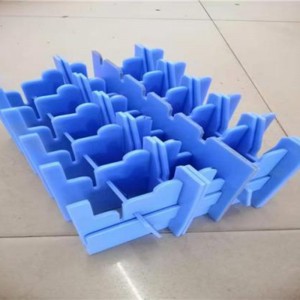

LOWCELL polypropylene(PP) foam sheet material box assembled by fasteners

Material boxes are commonly used in factories.Mostly use polypropylene(PP)foam sheet(expanded 2 times) as Material box. Harder than 3 times foamed board.Because the sheet is closed cell foam extrusion,so it is not easy to accumulate ash.The material box made of polypropylene(PP) foam sheet will be lighter.This is its advantage.The connecting fastener used in the material box was designed by our company.At present, the fastener is more suitable for board with a thickness of 4-5mm, the most used thickness for making material boxes.Our polypropylene(PP) foam sheet can make many kinds of boxes.