OEM/ODM Manufacturer Machining Polypropylene - LOWCELL polypropylene(PP) foam sheet material box assembled by fasteners – Bluestone

OEM/ODM Manufacturer Machining Polypropylene - LOWCELL polypropylene(PP) foam sheet material box assembled by fasteners – Bluestone Detail:

Why use polypropylene(PP) foam board as material box?

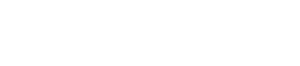

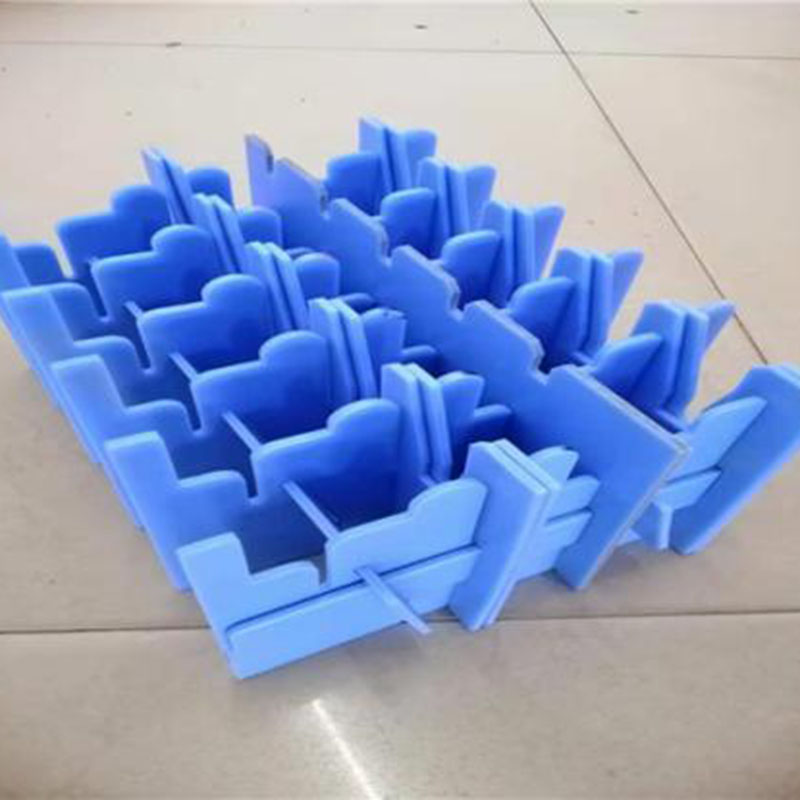

The material box is suitable for various industries and occasions with a wide range of applications.It can be used to store food, with convenient cleaning, convenient parts turnover, neat stacking and easy management.Reasonable design, excellent quality. It is applicable to transportation, distribution, storage, circulation and processing in factory logistics.If you choose polypropylene(PP) foam board as material box.Light weight to meet the requirements of box weight.Good strength to deal with the damage when falling.According to the maximum load requirement of the box, choose different thickness of the board.Polypropylene material is resistant to high temperature and corrosion.Heat insulation, sound insulation,machinability,low temperature resistance, resilience, etc. are very good.It can be made into not only a material box, but also a material box with a cover.

Why use the fasteners to assembled the material box?

The material box can be made by various processing methods.For example, electrode welding, Hot melt welding,fix with nails, etc.The technical requirements of electrode welding are relatively high.But the polypropylene(PP) foam sheet material box assembled by our fasteners is relatively simple to operate.Only need to order the foam sheets and fasteners, which can be assembled by yourselves.It can also save labor cost and shipping rates.As assembled boxes are easily damaged during transportation, we usually sell only polypropylene(PP) foam boards not finished products.

If you are interested in our boards, please contact us.

Product detail pictures:

Related Product Guide:

Along with the "Client-Oriented" small business philosophy, a rigorous high-quality handle system, highly developed producing machines and a powerful R&D group, we always supply high-quality products and solutions, fantastic services and aggressive costs for OEM/ODM Manufacturer Machining Polypropylene - LOWCELL polypropylene(PP) foam sheet material box assembled by fasteners – Bluestone , The product will supply to all over the world, such as: Madras, Kenya, Swedish, Honest to every customers are our requested! First-class serve, best quality, best price and fastest delivery date is our advantage! Give every customers good serve is our tenet! This makes our company get the favour of customers and support! Welcome all over the world customers send us enquiry and looking forward your good co-operation !Please your inquiry for more details or request for dealership in selected regions.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!